Select all the inside features and then click the Create Profile Toolpath icon on the toolpaths flyout menu on the right. The cut will be the inside features of the wing spar. I will explain one cut using the wing_spar example file that comes with Cut2D. Here is what a typical laser might look like. This does not apply so just put in any reasonable value. If your laser can use this for beam power then set it for the number that would yield max power, otherwise a value of 1000 should be fine.Īgain, this is a default number that can be changed at each tool path, so pick number that is close to t typical number you might use.

You could use it to control beam power if your laser supports that. This value is also not really important at this point. This does not apply for lasers, because we will not be doing pocketing. This default value can always be changed when you are setting up a toolpath if you actually want to play games with multiple passes. I suggest setting this to a value of 1 inch. You do want to make sure this value is larger than any value that you will use when specifying tool paths so the cut is always one pass. You cannot realistically use Cut2D to control the depth of a laser cut. If you want to be as accurate as possible, you could define multiple tools based on different materials and thicknesses. The amount you are less than the inch will give you the beam diameter. An easy way to determine this is to cut out a 1 inch square on the geometry lines with no offsets. This way you do not need to remember what speeds and feeds are needed for each material.Ĭut2D will use this when calculating how much to offset the cut line from the geometry when cutting inside or outside features. You could name the tools “1/8 Plywood laser cut” or “6mm Acrylic laser cut”, for example. If you want to go crazy, you could setup dozens of tools with default values that work well with certain materials. Many values you set are just default values and can be changed when you use the tool for a cut. In reality most lasers are not going to cut anything thicker than an inch or so due to beam divergence. The major difference is that it has an “infinite” depth of cut. It is basically a cutting cylinder with a fixed width. The beam can be thought of as an end mill. The first step is to setup a “tool” in the tool library for the laser beam. I will just explain the differences when using a laser cutter.

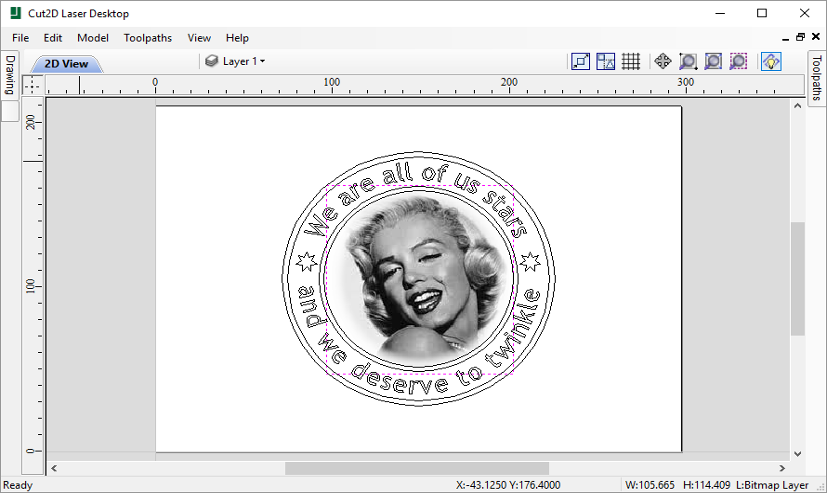

Vectric cut2d reviews how to#

I am not going to explain how to use Cut2d. All Z movement is removed from the post processor, so the actual Z values used below are not going to affect your machine while cutting.

I wrote a blog post about it and the file is available here. I created one for Aspire last year and found that it worked perfectly for Cut2D as well. It is also very easy to customize your own post processor.

There are several flavors of Mach3 post processors that will work right out of the box for most mills and routers. The Vectric products ship with 100+ pre-made post processors. They did say that they are not really interested in selling it for laser use only because the program may be confusing to them and they only want 100% satisfied customers. This is probably due to the fact that I already own their top of the line product.

Vectric cut2d reviews free#

Vectric was gracious enough to give me free evaluation copy. A forum member recently asked for help using Cut2D. I started with VCarve, then upgraded to Aspire. While I would not recommend purchasing it to only use on a laser, people who have both a CNC router and a DIY laser will find this to be a very capable and inexpensive product.

It is primarily designed for traditional mills and routers.

Vectric cut2d reviews code#

It is designed to quickly and easily import DXF plus several other vector formats and create G Code for CNC cutting.

0 kommentar(er)

0 kommentar(er)